LCD/OLED screen Mura detectionReturn >>

2018-07-28 4985

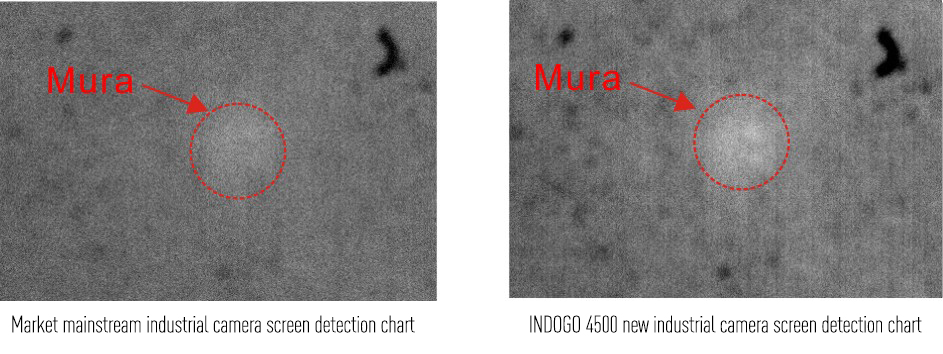

Mura detection is different from general pixel dead point and scratch defect detection. It is the light and dark color difference introduced in the LCD/OLED manufacturing proccess, with no obvious detection means, therefore simply raising the camera resolution cannot achieve the detection requirements of lower contrast Mura. . The Indigo Imaging team innovatively introduced a signal quantization recognition algorithm and successfully developed a high-resolution camera with ultra-high defect detection rate – the INDIGO 4500, which can not only realize a micro defect detection of 5 microns, but also can reach an ultra-low level of 1%, far beyond the industry standards.

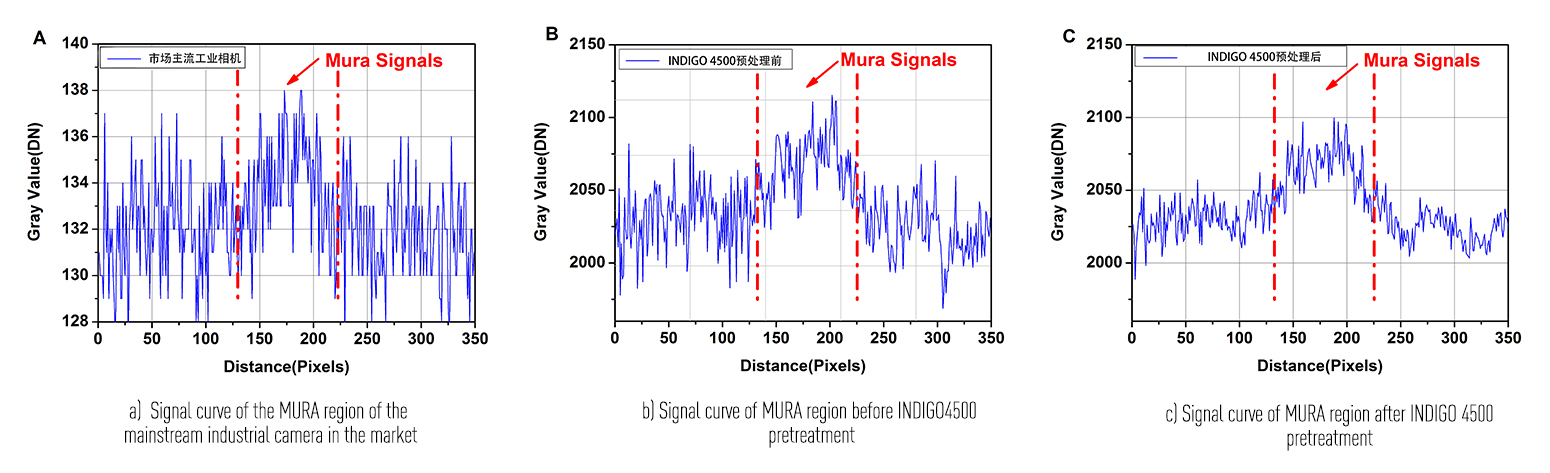

As shown in the figure, the INDIGO 4500 adopts a new technology mode. The oscillation amplitude of INDIGO 4500 signal curve (Figure B) has reduced largely, the same as its quantization error, as a result the Mura signal recognition accuracy has been significantly improved compared with the Mura signal curve (Figure A) detected by the mainstream machine vision cameras on the market; On the other hand, based on the temporal and spatial correlation of the noise, the camera accomplishes a multiple iterations of pre-processing, under the premise of not affecting the real signal, to separate the signal to be measured and the jitter of the background better, as shown in Figure C: Compared with the un-preprocessed image, the signal-to-noise ratio of the INDIGO 4500 is improved by more than 2 times after pre-processing, and the sensitivity of the Mura signal detection can be improved by 78% on the original basis, which realizes the precise detection of micro-signals.

INDIGO 4500High Resolution Camera

7920x5436@2.8μm 16fps @7920x5436 Support FFC, DPC Support hardware/software trigger Firmware update